Water Injection Technology

Fluid injection allows for complex tubular designs, realized in a regular injection molding process. Might it be a cooling pipe, or a complex bike frame structure, water-injection-technology is one of the most precise and cost-effective molding processes. It is a proven process and easy to integrate into most injection molding units.

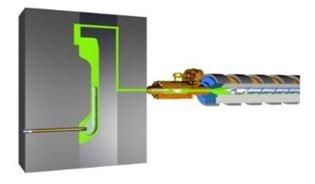

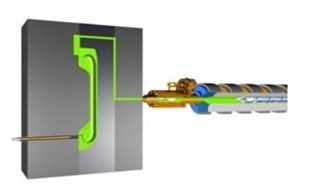

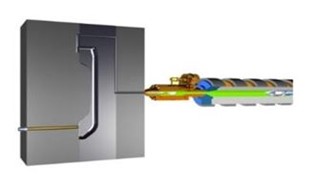

Polymer Injection Process

Melt ready for injection

Complete filling of cavity

Molten core pushed back into barrel

Completed water injection process

Bike Frame

One of the key benefits of water injection technology is independent local production which avoids offshore sourcing. Technology and smart design made domestically!

Liftgate

Functional integration and perfect surface appearance, all available in a cost effective TPO structure. Just one of many examples to prove the low cycle time in large body parts.

Wheelbarrow

Mechanical strength paired with colorful product options. This application is a perfect example that flow length is not a limitation for fluid injection technology.